Every building, vehicle, or venue has its own set of challenges and requirements, especially when it comes to materials like curtains that play a dual role in aesthetics and functionality. If you’re wondering whether inherently flame-retardant polyester curtain fabric can be tailored to meet unique fire safety standards beyond the usual certifications, the answer is a resounding yes—and here’s how we make it happen.

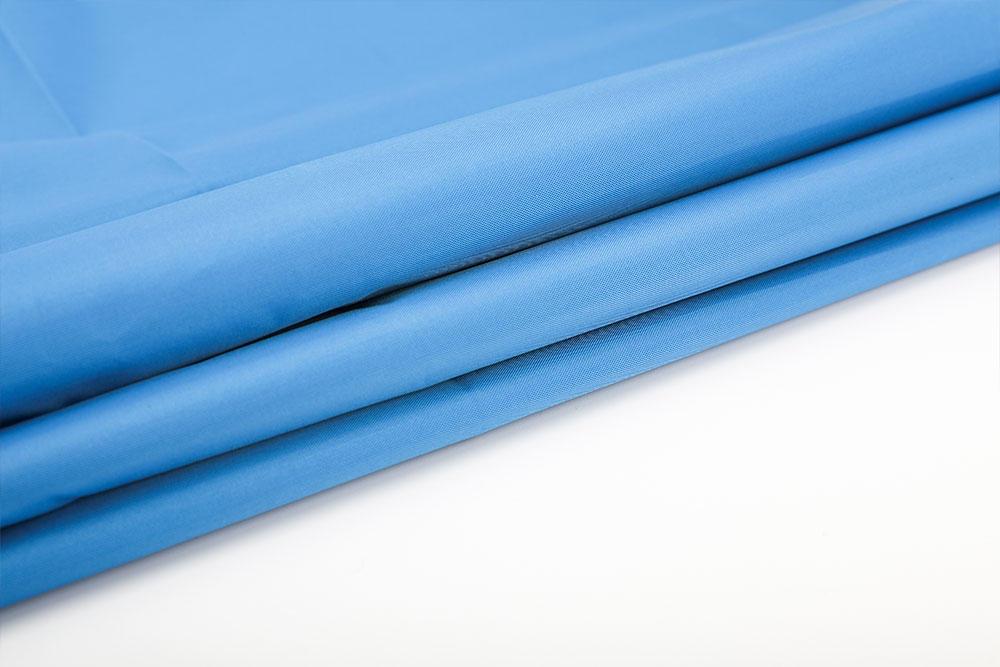

At the heart of our product lies innovation and adaptability. Our flame-retardant polyester yarn isn’t just about meeting basic compliance; it’s engineered to push boundaries. For instance, while many fabrics are designed to pass certifications like GB20286-2012, BS 5867, or NFPA 701, we understand that some projects demand more. Whether it’s achieving a higher oxygen index for extreme environments or ensuring minimal smoke toxicity in enclosed spaces, our team thrives on customization. By embedding flame-retardant chemicals directly into the polyester masterbatch, we create a foundation that allows us to tweak properties without compromising the core integrity of the material.

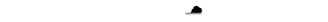

So, what does this mean for customers with unique needs? Imagine you’re designing a high-end hotel where fire safety is paramount, but so is luxury. You need curtains that not only resist flames but also drape beautifully and feel soft to the touch. Or perhaps you’re outfitting a train carriage where weight, durability, and fire resistance must coexist seamlessly. These scenarios require a fabric that goes beyond the standard checklist. That’s where our expertise shines. We work closely with architects, interior designers, and safety engineers to develop solutions that align perfectly with their vision and technical specifications.

One of the standout features of our inherently flame-retardant polyester fabric is its versatility. For example, if a client requires enhanced UV resistance for sun-exposed areas, we can adjust the formulation to ensure the fabric withstands prolonged sunlight without degrading. Similarly, if low smoke emission is critical—say, for an airplane cabin—we can fine-tune the chemical composition to minimize smoke production even further. And because the flame retardancy is intrinsic to the fabric, these customizations don’t come at the cost of washability or long-term performance. No matter how many times the fabric is laundered, its fire-resistant properties remain intact.

But customization isn’t just about tweaking the science; it’s also about delivering practical value. Take hospitals, for instance. Here, curtains aren’t just decorative—they’re barriers that protect patient privacy and prevent the spread of infections. Our IFR polyester fabric can be treated with antimicrobial finishes while retaining its fireproof qualities, offering a dual layer of protection. Schools, on the other hand, might prioritize abrasion resistance and ease of maintenance, which we address by reinforcing the fabric’s durability during production. Each project is unique, and our goal is to provide a solution that ticks every box.

Of course, none of this would be possible without rigorous testing and quality assurance. When a customer approaches us with specific requirements, we don’t just rely on theoretical adjustments—we put the fabric through its paces. From simulating industrial laundering conditions to exposing it to extreme heat and UV radiation, we ensure that every modification meets or exceeds expectations. And because we’ve been in the flame-retardant textile industry for over two decades, we bring a wealth of knowledge to the table, allowing us to anticipate potential challenges and address them proactively.

Another aspect worth highlighting is sustainability. As global awareness around eco-friendly practices grows, many clients are looking for inherently flame-retardant polyester fabrics that align with green building standards. While maintaining fire safety, we strive to incorporate environmentally friendly processes, such as using halogen-free flame retardants and reducing water consumption during manufacturing. This balance between performance and planet-consciousness is something we take pride in, and it’s a key consideration for clients who want to future-proof their projects.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español