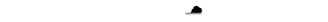

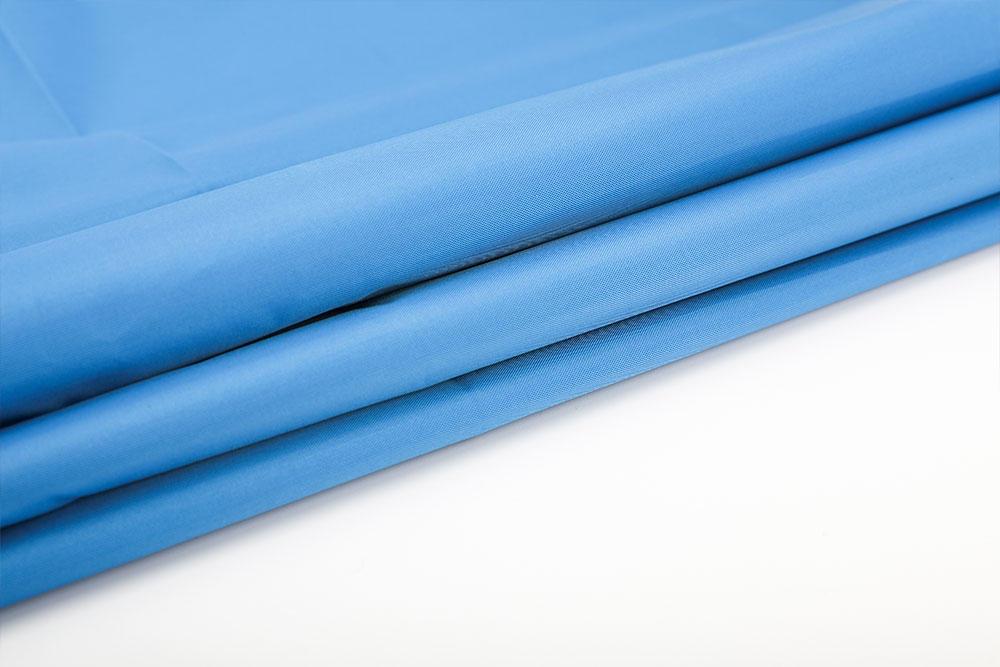

Aramid flame retardant fabric has the advantages of heat resistance, high strength, high wear resistance, good flexibility, low shrinkage, stable chemical structure, no melting droplets when burning, and no toxic gas. Widely used in fire protection, military clothing, petroleum industry, power industry, natural gas industry, metallurgy industry, coal industry, aviation industry, marine industry, automobile and other industries.

The flame retardant fabric woven with aramid fiber has good stability, can be used for a long time at a temperature of 250 ℃, and its thermal shrinkage rate is only 1%. The softening temperature of the fiber is 373 ℃, and it begins to decompose when it exceeds 400 ℃. During the decomposition, the fabric surface thickens, the fiber expands, and 900-1300 ° C outside the fabric surface is isolated from heat transfer without cracking.

Aramid flame-retardant fabrics can be added with anti-static fibers when weaving fabrics, and the fabrics can be treated with oil and water repellent. The resulting aramid flame-retardant clothing has the following functions:

Permanent heat and flame resistance

Permanent antistatic

Permanent resistance to acid and alkali and organic solvents

High strength, high wear resistance, high tear resistance

In the event of fire, no droplets are produced and no toxic gas is produced

When the cloth is burned, the cloth surface is thickened, and the sealing performance is enhanced without cracking.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español