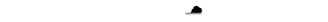

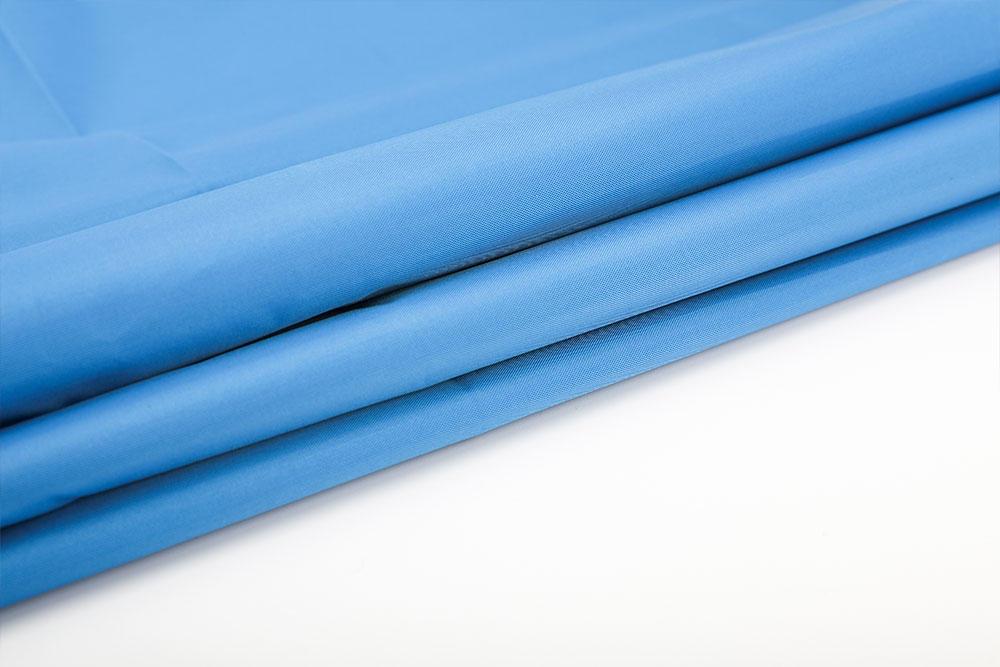

It is the fabric that will provide the protection from the elements, maintain a warm dry interior, stand up to rugged handling and be of good value for your money. This is asking a lot from most fabrics and is the reason we offer several different fabric constructions in our tents and tipis. Each fabric we use provides a little different combination of important features and benefits for your consideration.

Fabric has been treated with a non-permanent, registered, FR chemical at the Mill by a certified applicator.

Traditionally, IFR fabrics have been defined as fabrics constructed with yarns manufactured with FR additives. This process imparts Permanent Flame Retardant properties to a fabric over its service life.

You may be wondering why tents are even made with a chemical coating, to begin with, and what that means for us campers. Well, it turns out that flame retardant chemicals are applied to almost every tent in North America in order to meet flammability standards that were created in 1976. Although the standards were revised in 1995, they are still years behind the game and greatly in need of another revision.

During the 70s, highly flammable paraffin coated materials were used, much different from the synthetic materials used in modern tent designs. Simply put, these flammability standards were at one time necessary, protecting the unwitting campers from losing their highly flammable tents to a stray spark.

So what does this mean for you today? Although your tent will still be less likely to go up in smoke if you pitch it a bit too close to the flames, we now know that you are risking exposure to flame retardant chemicals which have been linked to several negative health effects.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español