When comparing the installation process of fabric air ducts to that of traditional metal ducts, several key differences highlight the advantages and unique features of each system. Fabric air ducts, also known as textile ducts or fabric air dispersion systems, have gained popularity due to their ease of installation, flexibility, and efficiency. These modern systems stand in contrast to conventional metal ductwork, which involves more complex installation procedures and often requires more labor and materials.

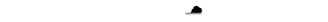

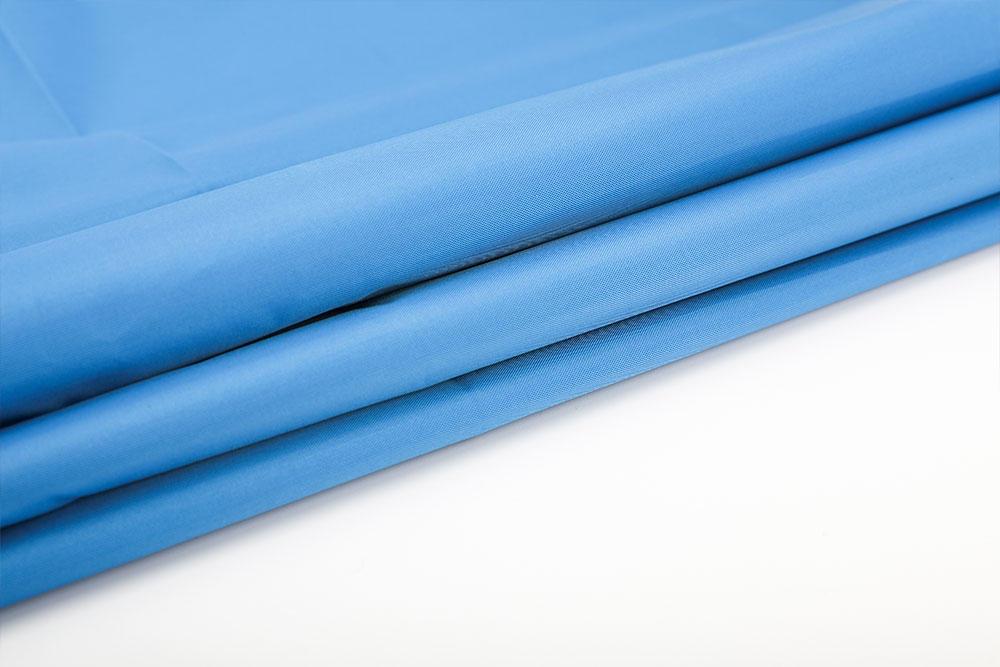

The installation of fabric air ducts is notably simpler and more streamlined than that of traditional metal ducts. Fabric ducts are lightweight and flexible, allowing them to be easily maneuvered and adjusted during installation. This flexibility enables quicker and less labor-intensive installation processes. Unlike metal ducts, which often require precise cutting, fitting, and sealing, fabric ducts can be installed with fewer tools and less specialized skill. The fabric is usually pre-fabricated and designed to be hung from supports or brackets, which means that installers can simply hang the ducts, connect them to the air handling units, and secure them in place. This ease of handling reduces installation time and minimizes disruption in the workspace.

In contrast, traditional metal duct installation involves a series of detailed steps that include measuring, cutting, fitting, and sealing sections of metal ductwork. Metal ducts are heavy and rigid, which requires more effort to handle and install. The installation process often demands more extensive coordination, including precise measurements and additional supports to ensure structural integrity. Metal ductwork also requires sealing at joints and connections to prevent air leakage, which adds another layer of complexity and time to the installation process. Furthermore, metal ducts can necessitate additional insulation to address condensation issues, which can further complicate the installation and increase costs.

One of the significant advantages of fabric air ducts is their ability to be customized and adapted on-site. Fabric air ducts can be easily trimmed or adjusted to fit specific installation spaces, providing flexibility in design that metal ducts do not offer. This adaptability is particularly beneficial in environments where space constraints or architectural features pose challenges. Additionally, fabric ducts are often pre-treated with flame retardant and anti-bacterial properties, which can enhance their performance and safety without the need for additional treatments during installation.

The installation of fabric air ducts offers several advantages over traditional metal ducts, including reduced installation time, lower labor costs, and greater flexibility. Fabric ducts simplify the process by being lightweight and easy to handle, while traditional metal ducts require a more intricate and labor-intensive approach. The ease of installation and adaptability of fabric air ducts make them an attractive option for both new constructions and retrofit projects, particularly in large, open spaces where efficient air distribution and minimal disruption are priorities.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español