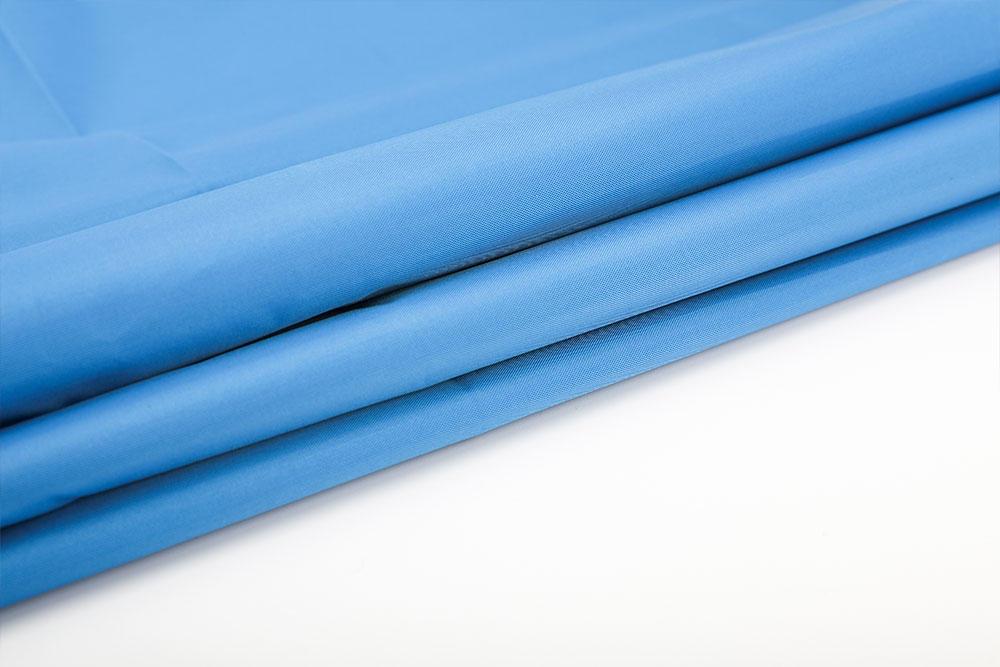

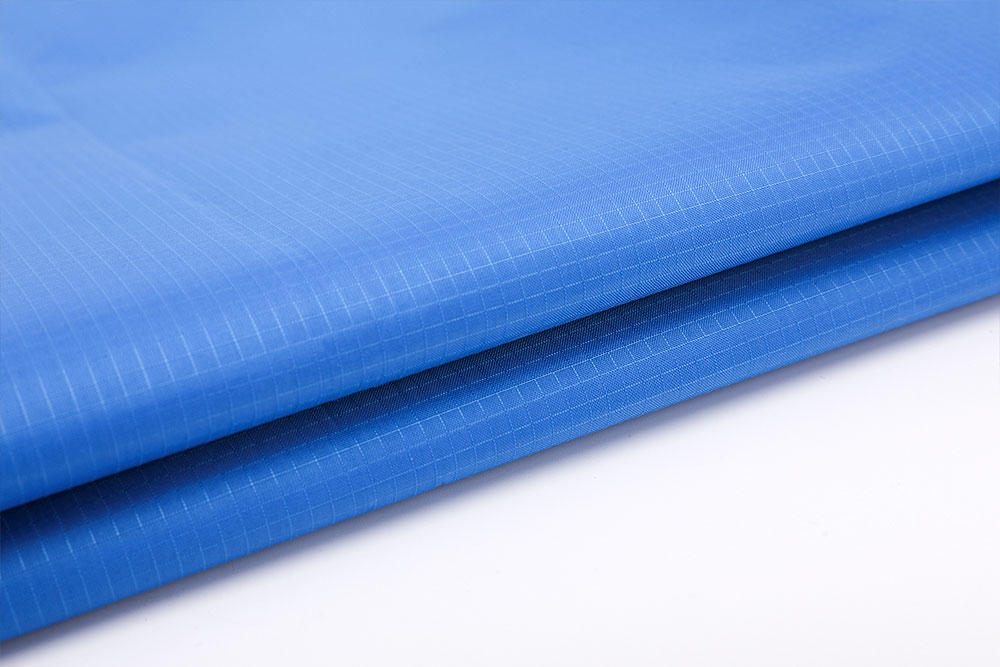

As the demand for high-performance materials continues to rise across various transportation sectors, IFR seat cover fabric is finding exciting new applications beyond its traditional use in high-speed rail systems. Thanks to its combination of flame-retardant properties, comfort, durability, and aesthetic flexibility, this specialized textile is becoming a go-to solution in environments where safety and passenger experience are paramount. From aircraft cabins to cruise ships, and even to the interiors of premium electric vehicles and autonomous shuttles, these fabrics are adapting to new challenges while maintaining the core characteristics that have made them reliable in rail systems.

In the aviation industry, where strict safety regulations coexist with heightened expectations for comfort, fireproof velour and flame-retardant jacquard seat fabric options offer an ideal blend. The lightweight yet strong structure of these materials contributes to overall weight management in aircraft design, while the inherent fire resistance aligns with global aviation standards such as FAR 25.853. Additionally, their ability to be dyed in custom colors or patterns provides airlines with a way to align cabin interiors with branding strategies, creating a cohesive, premium feel without compromising safety or longevity.

On the water, IFR seat fabrics have begun making waves in commercial and recreational marine vessels. Cruise ships and passenger ferries require seating materials that resist not only fire hazards but also humidity, salt exposure, and frequent use. Seat cover fabrics designed for these applications are now being treated for enhanced mold resistance and easy cleaning, making them ideal for marine interiors where both performance and appearance must be maintained over extended periods. With the increasing number of people opting for leisure travel on luxury vessels, the visual and tactile quality of seat upholstery plays a growing role in customer satisfaction.

The rise of next-generation transport—think autonomous public shuttles, electric buses, and even space tourism concepts—has further expanded the relevance of IFR seating textiles. These futuristic transport modes call for seating solutions that meet evolving safety requirements while supporting minimalist, tech-driven design aesthetics. Manufacturers are now requesting seat cover fabric that offers sleek visual impact, high resistance to wear, and compatibility with built-in sensors or smart upholstery systems. In response, fabric producers are working closely with designers and engineers to tailor solutions that don’t just meet today's needs but anticipate tomorrow’s.

For decision-makers in these sectors, investing in IFR-grade seat cover fabric isn’t just about compliance—it's about making a long-term commitment to quality, safety, and passenger well-being. Our experience collaborating with transport manufacturers worldwide has shown that durable, customizable, and regulation-compliant fabrics can significantly reduce lifecycle costs and maintenance demands. Whether the goal is to outfit a fleet of aircraft or spec a new electric bus model, choosing the right seat upholstery fabric is a critical part of delivering a modern, safe, and comfortable travel experience.

As a dedicated manufacturer and supplier, we understand the importance of merging technical excellence with market responsiveness. That’s why our seat cover fabric solutions are not only certified to meet national and international fire safety standards but also developed with adaptability and customization in mind. Whether you’re building the future of transportation or upgrading existing systems, we’re here to provide dependable, well-engineered fabric options designed to move with your vision.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español