Selecting the right fire-retardant blackout fabric often comes down to understanding how treated and coated options differ in structure, behavior, and use. Both are designed to block light and reduce fire risk, making them essential in commercial settings such as hotels, hospitals, schools, and care facilities. The distinction lies in how these fabrics achieve their fire resistance and how that influences durability, appearance, and long-term performance. Buyers looking to balance safety, function, and budget will benefit from a closer look at how each type behaves under real-use conditions.

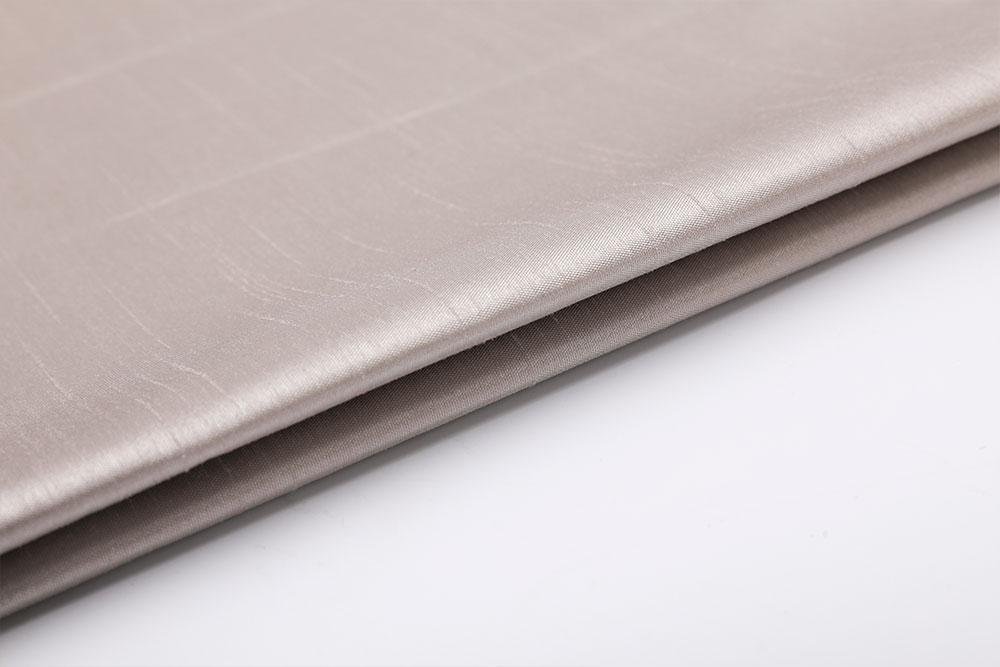

Treated fire-retardant blackout fabric starts as a conventional textile, later finished with a flame-retardant chemical. This process makes it cost-effective and easy to produce in a range of decorative finishes, including gilded or printed options. Its visual appeal and smooth drape make it a popular choice for areas where style is just as important as light control. However, the chemical treatment sits on the surface of the fabric and doesn’t penetrate the fibers. This limits its resistance to washing or heavy moisture exposure, as frequent contact with water can strip away its fire-retardant qualities over time.

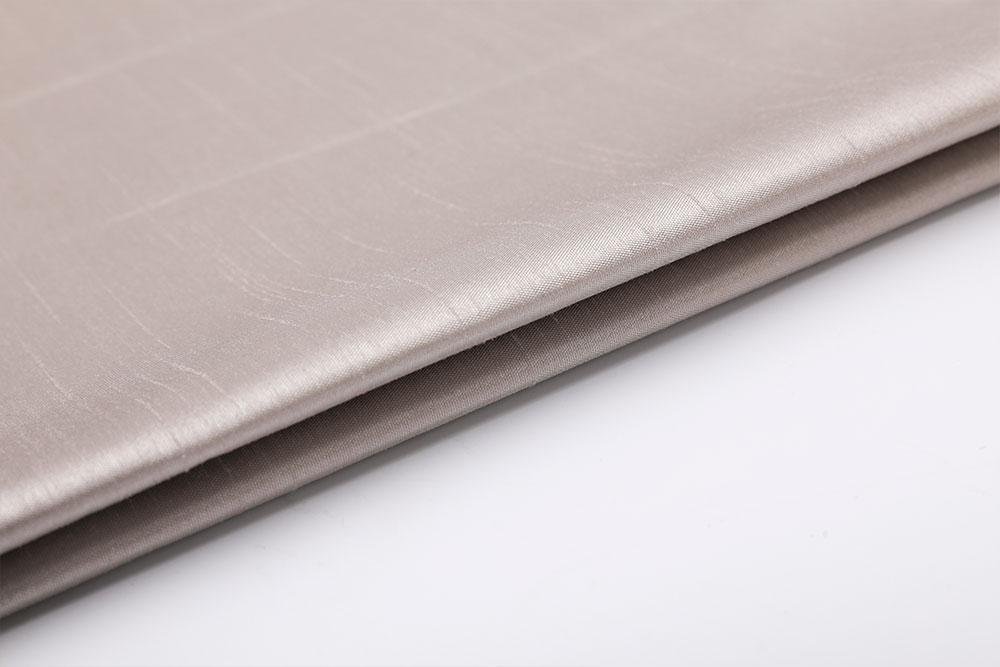

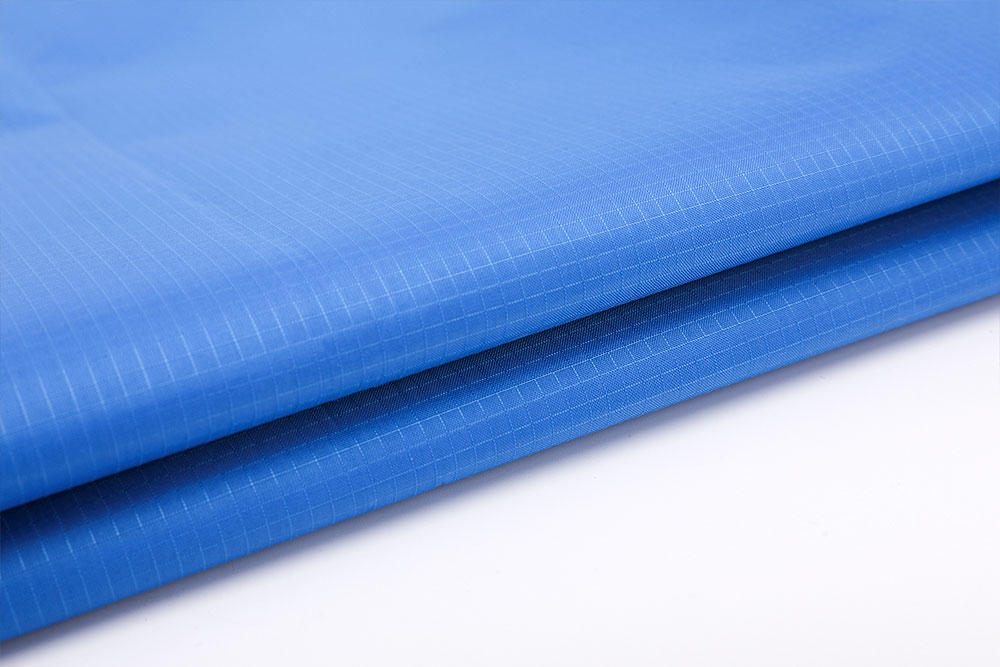

Coated fire-retardant blackout fabrics are constructed differently. These materials feature a fire-resistant layer applied during manufacturing, usually as part of a multi-pass coating system. A 3-pass or 4-pass blackout fabric ensures complete light blockage while embedding fire-retardant properties into the structure itself. The result is a thicker, more opaque material that excels in areas needing total blackout, such as hotel suites or medical examination rooms. However, the coatings used are also sensitive to cleaning processes and are not washable. Additionally, some coatings may emit toxic smoke under high heat, a concern to weigh carefully depending on a building's safety protocols.

One of the main points of comparison is longevity. Treated blackout fabrics tend to be lighter and retain their color and texture longer in static, dry environments. Coated blackout fabrics, with their layered construction, are typically more rugged in terms of blackout efficiency but may show signs of wear sooner if used in high-contact areas or exposed to bending and folding. Their added weight can also influence how they are installed, especially in large windows or ceiling-mounted tracks.

The choice between the two depends largely on how the space functions and what expectations exist for blackout quality and fire safety. A classroom, where noise and light reduction are important but cleaning is infrequent, may do well with a treated fabric that offers a soft appearance and basic fire protection. A hotel room that needs to deliver complete darkness for guest comfort will likely benefit from the higher performance of a coated fire-retardant blackout fabric, despite the added cost and handling considerations.

Kylin offers both types because each serves a distinct purpose. Our treated fire-retardant blackout fabrics are designed for spaces that require affordability and design flexibility, while our coated options meet the demands of full blackout coverage with built-in fire resistance. As a supplier deeply involved in the day-to-day needs of commercial furnishing projects, we know how to match material to function. Clients trust our knowledge, not just our product range, and we’re here to help them make informed, effective choices that stand up to real-world use.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español