When it comes to designing umbrella fabric that’s as stylish as it is functional, the secret lies in the marriage of advanced printing techniques and innovative coatings. These elements not only elevate the aesthetic appeal of the material but also enhance its performance, making modern umbrellas a true fusion of art and technology. From vibrant prints to shimmering finishes, let’s explore how high-tech processes are transforming umbrella textiles into masterpieces of design and utility.

At the heart of this transformation is the cutting-edge printing technology used to bring umbrella fabrics to life. Unlike traditional methods, which often result in dull or easily faded designs, today’s high-tech printing processes ensure that colors remain vivid and long-lasting, even under harsh conditions. This is particularly important for umbrella fabric, which is constantly exposed to sunlight, rain, and wear. By using specialized inks and precision application techniques, manufacturers can achieve intricate patterns and bold hues that resist fading, no matter how intense the UV exposure. For instance, imagine an umbrella that transitions from colorless to purple under the sun, thanks to light-sensitive powders embedded in the fabric. Such innovations not only make umbrellas visually captivating but also add an interactive element that delights users. And because these prints are applied with meticulous care, they maintain their integrity even after repeated use, washing, or folding—ensuring your umbrella stays as striking as the day you bought it.

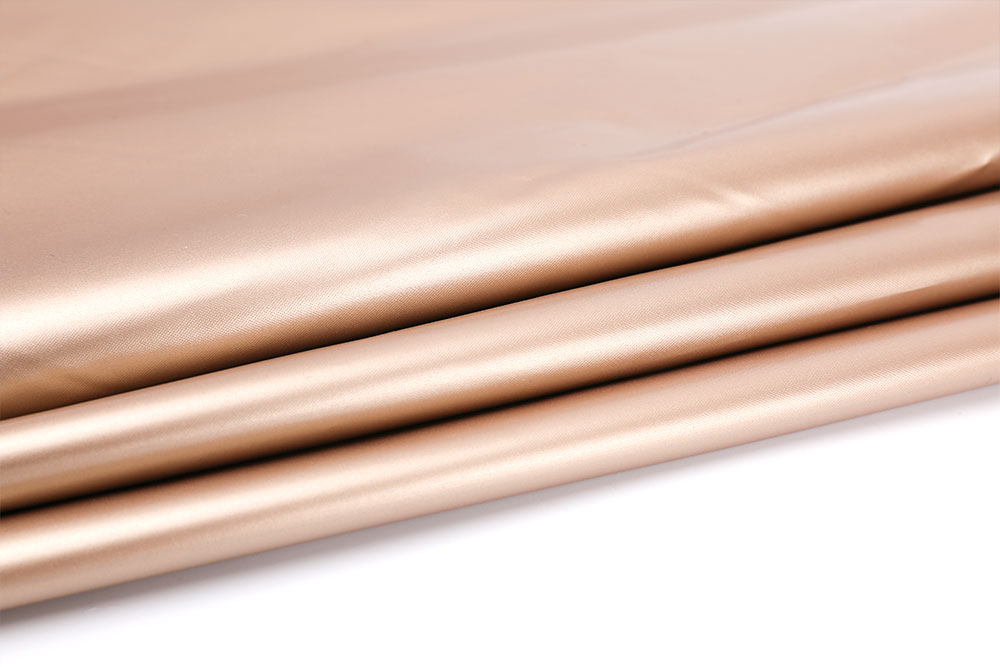

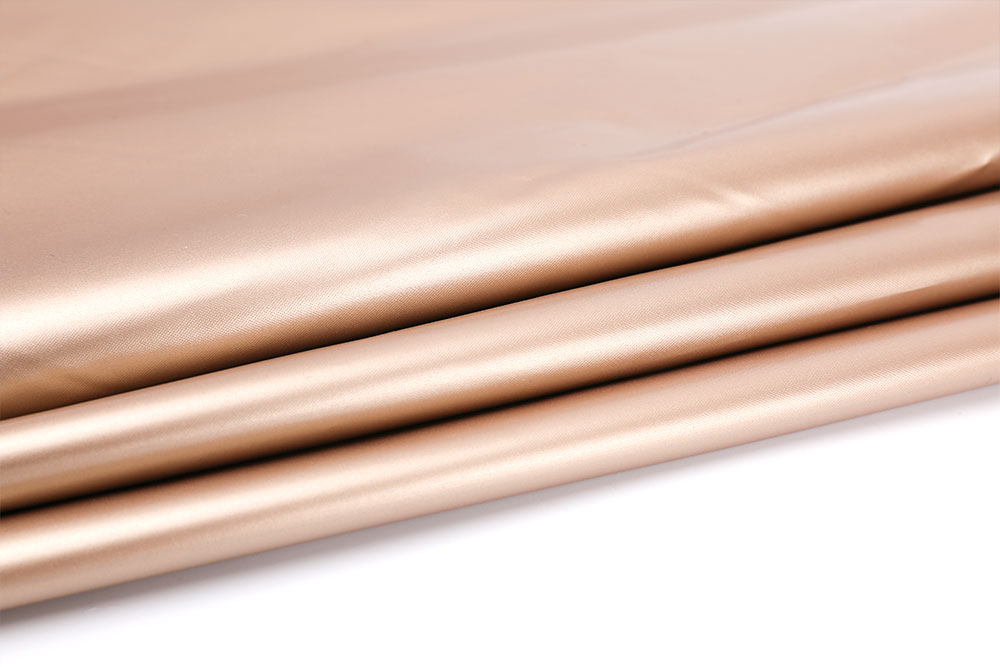

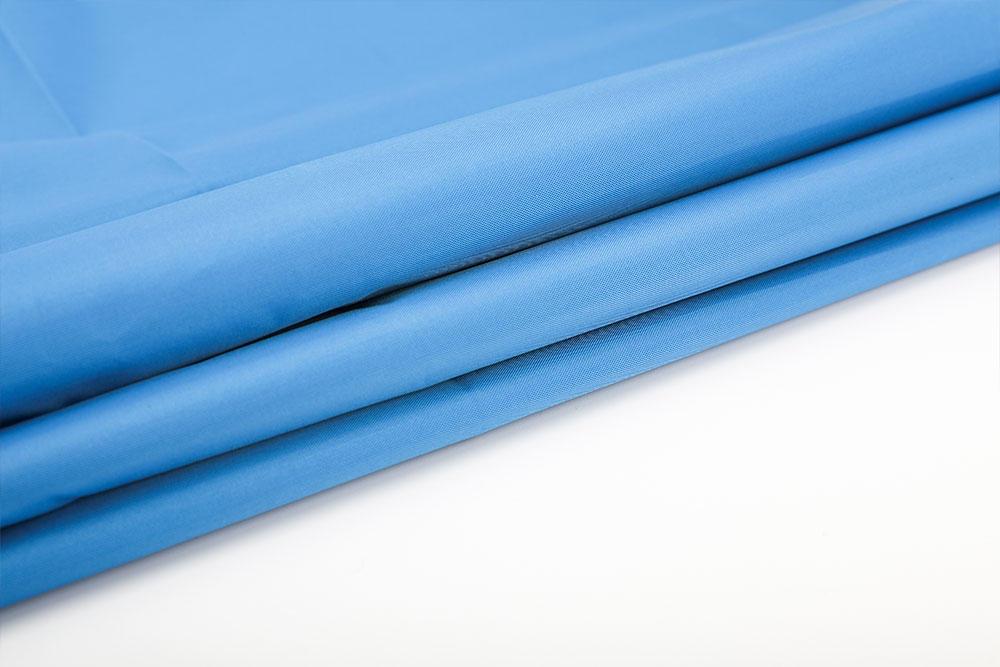

But printing is just one piece of the puzzle. The coatings applied to umbrella fabric play an equally vital role in defining its character and functionality. Take, for example, the use of fluorescence, pearl, and silver powder coatings, which create a stunning contrast between the interior and exterior surfaces of the material. These coatings don’t just enhance the visual appeal; they also serve practical purposes. Fluorescent coatings, for instance, can increase visibility during low-light conditions, making them ideal for safety-focused designs. Pearl coatings, on the other hand, impart a luxurious sheen while reflecting sunlight, contributing to the fabric’s cooling properties. Meanwhile, silver powder coatings can amplify UV resistance, ensuring the umbrella fabric remains durable and protective over time. Together, these treatments allow manufacturers to craft textiles that are as versatile as they are beautiful, catering to a wide range of consumer preferences and needs.

What makes these advancements even more exciting is their potential for customization. Whether you’re looking for a sleek, minimalist design or a bold, eye-catching pattern, modern printing and coating technologies offer endless possibilities. For businesses, this means the ability to create branded umbrellas that align perfectly with their identity, from corporate logos to unique seasonal motifs. For individual consumers, it opens the door to personalized products that reflect their personality and style. And because these processes are highly scalable, they can accommodate everything from small-batch custom orders to mass production without compromising quality or consistency.

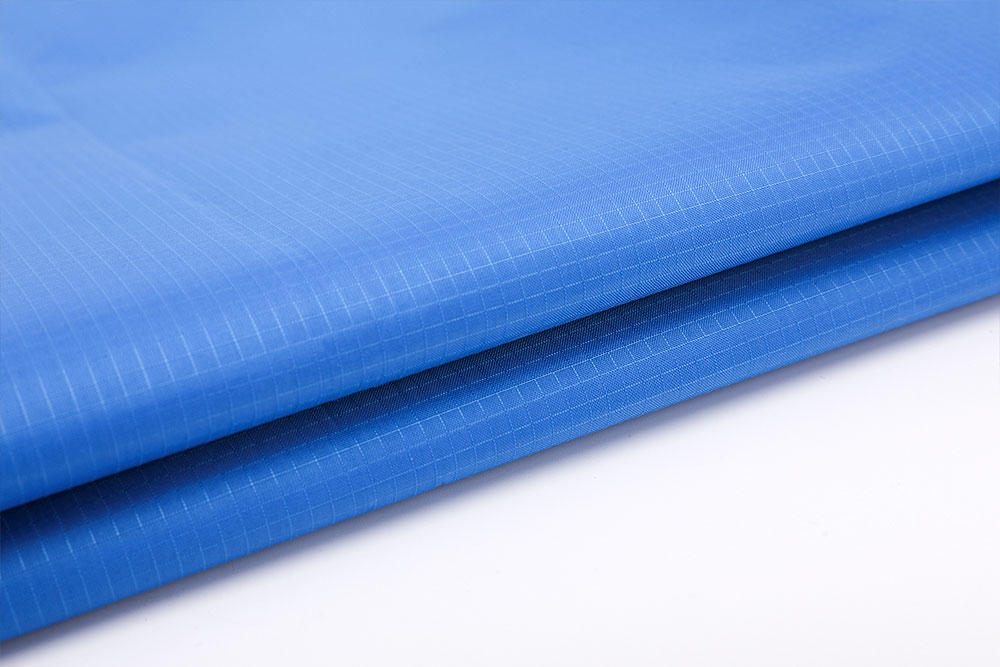

Of course, none of this would be possible without a deep understanding of the materials themselves. The base fabric used in umbrellas—often treated with blackout PU or layered with vinyl—provides the perfect canvas for these enhancements. Its inherent durability and weather-resistant properties ensure that the prints and coatings adhere seamlessly, creating a cohesive final product. Moreover, the fabric’s texture and structure play a crucial role in how these finishes interact with light and movement, adding depth and dimension to the overall design. For instance, the subtle rustling sound and crease retention of certain umbrella fabrics can enhance the tactile experience, making the product feel as premium as it looks.

The world of umbrella fabric has come a long way from simple, utilitarian designs. Thanks to high-tech printing and innovative coatings, today’s umbrellas are not just tools for protection but also statements of style and innovation. Whether you’re drawn to the mesmerizing color-changing effects, the reflective elegance of pearl finishes, or the practical benefits of UV-reflective coatings, there’s no denying that modern umbrella textiles are a testament to human creativity and ingenuity. So, the next time you unfurl your umbrella, take a moment to appreciate the intricate craftsmanship behind its fabric—it’s a masterpiece in motion, designed to keep you covered in both form and function.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español