IFR Chenille Curtain Fabric stands out in the textile industry for its unique blend of luxury and practicality, making it a preferred choice in upscale settings such as hotels, exhibition centers, and corporate offices. Understanding the manufacturing process behind this exceptional fabric not only highlights its quality but also reveals how its specific attributes contribute to its overall performance. The journey of creating IFR Chenille Curtain Fabric begins with carefully selected fibers, typically a blend of polyester and flame-retardant materials. This careful selection ensures that the fabric not only looks and feels luxurious but also adheres to strict safety standards for fire resistance. The fibers undergo a rigorous preparation process, where they are dyed to achieve vibrant colors that retain their hue over time, thanks to high color fastness. This step is crucial, as the fabric must withstand exposure to light and UV rays without fading, a characteristic highly valued in sunlit environments.

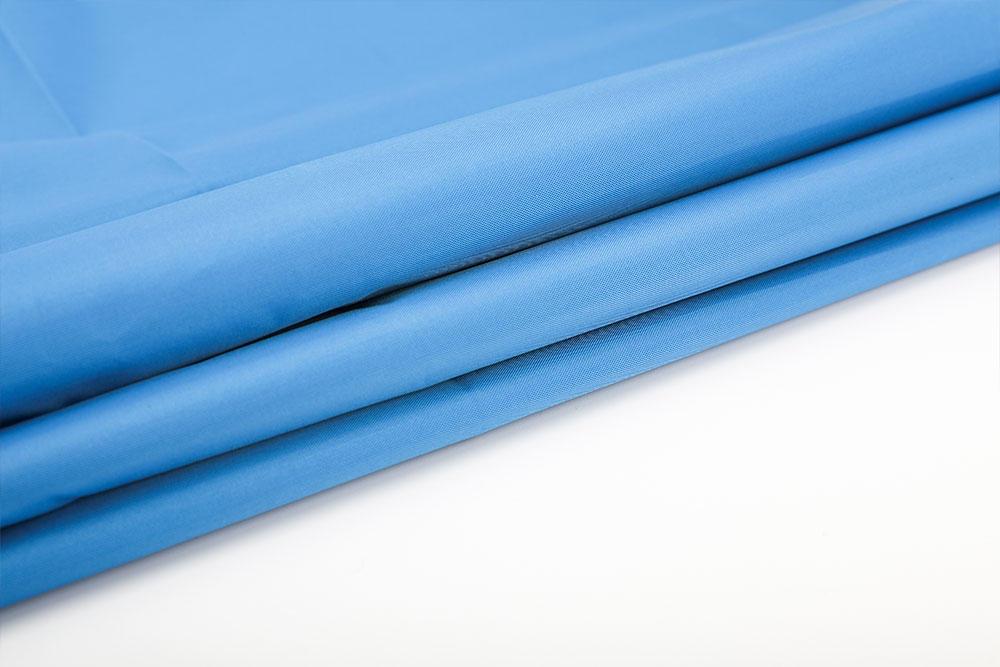

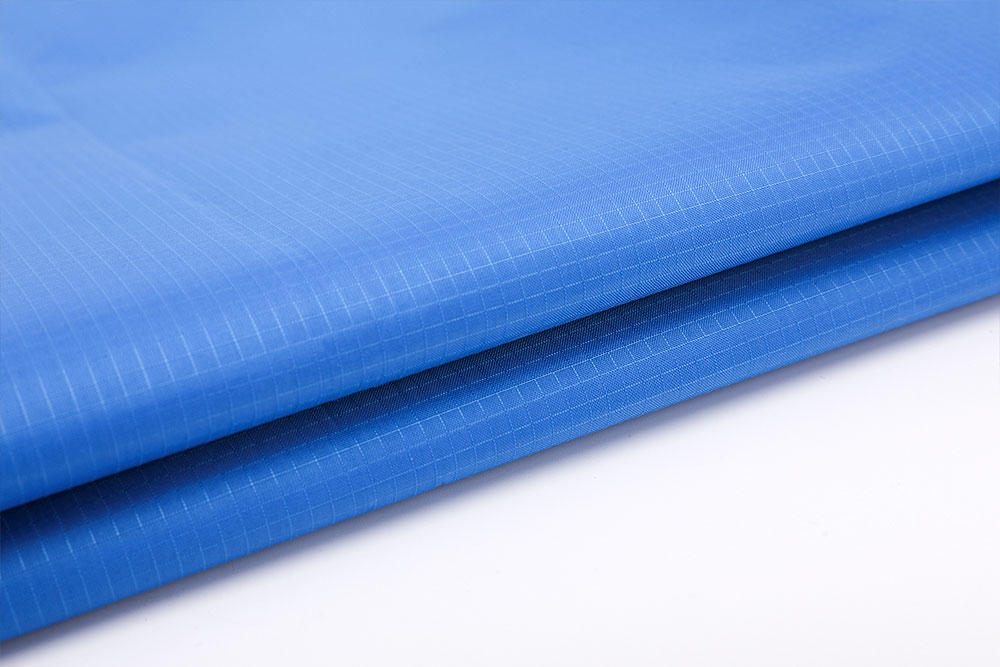

Once the fibers are dyed, they are woven into the characteristic chenille texture. The weaving technique creates a plush surface that offers a sumptuous feel while maintaining the fabric’s lightness despite its thickness. This unique texture not only enhances the visual appeal but also contributes to the fabric's drapability, allowing it to hang beautifully and complement various interior designs. The weaving process also incorporates air pockets, which enhance sound and thermal insulation properties. This means that IFR Chenille Curtain Fabric does more than just add aesthetic value; it contributes to a quiet and comfortable atmosphere, making it ideal for spaces where tranquility is essential.

The finishing touches are where the magic truly happens. After weaving, the fabric undergoes treatments that enhance its performance attributes. Flame retardancy is a primary concern for this IFR Chenille Curtain Fabric, and specialized treatments are applied to ensure it meets safety regulations while maintaining its softness and flexibility. Additionally, the fabric is treated for antibacterial and mildew resistance, which is particularly advantageous in environments prone to humidity or where cleanliness is paramount. This ensures that the curtains not only resist stains and odors but also help maintain a healthier indoor air quality. The final product boasts excellent water absorption, allowing it to act as a barrier against moisture while still being easy to clean.

One of the significant advantages of IFR Chenille Curtain Fabric is its versatility. With options ranging from ordinary shading, which blocks 50% to 60% of light, to high shading, which can block 80% to 95%, it can cater to a variety of lighting needs in different settings. This adaptability makes it suitable for high-end hotels and health facilities, where both aesthetics and functionality are key. Furthermore, its durability ensures that it remains a valuable investment over time. As long as it is cared for properly—mainly by avoiding excessive humidity—it maintains its qualities and appearance without significant deterioration.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español