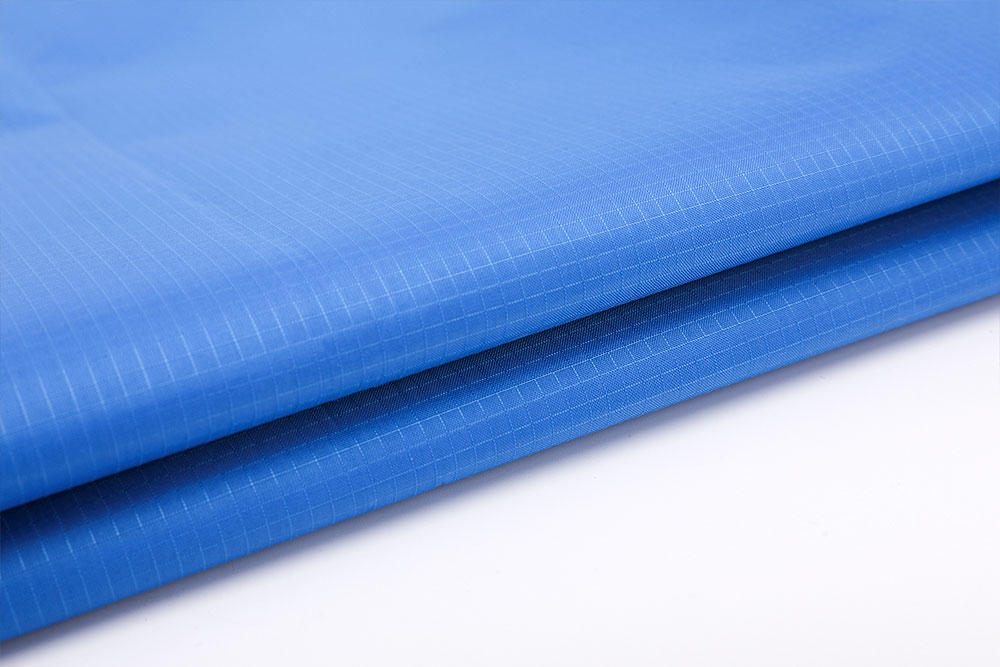

It is also very common FR 3 Pass Coated Blackout Curtain Fabric to use flame-retardant fabrics in car interiors, but many people don't know what kind of flame-retardant fabrics are used. Today I will take you to find out. Automotive textiles are generally required to have abrasion resistance, light resistance, flame retardancy, water and oil repellency, and anti-fogging properties due to their use environment, use characteristics, and safety considerations. In addition, automotive interior fabrics should also have good dye fastness, heat conduction, air and moisture permeability and other properties.

Automotive interior materials, especially textiles, must have good flame retardancy and flame retardancy. In this way, once the car is in danger of fire, it can ensure that passengers have enough time to leave, or reduce the risk of fire. Various fibers may be used in automotive textile materials. Their composition and chemical structure are different, and their thermal and combustion properties are also different.

Textiles are flammable products. During the combustion process, they not only release a lot of heat, but also produce harmful gases, endangering human health and life safety. Among the fibers of automotive textiles, cotton, polypropylene, acrylic, etc. have a limiting oxygen index lower than 20, which are high-combustible fibers; those with a 20~26 range include wool, nylon, polyester, etc., which are combustible fibers.

Among the 34 are aramid and modified acrylic fibers, which are non-combustible fibers; the ones above 36 are chlorinated fibers and glass fibers, which are non-combustible fibers. The flame-retardant fabrics used in car interiors can be extinguished when the fire is removed, and will not produce harmful gases. Even if it is ignited, it can be automatically extinguished in a short time. As the technology becomes more and more advanced, the performance of the flame-retardant fabrics It is getting better and better, and it can protect people's lives and property.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español