In the realm of industrial ventilation systems, the choice between Circular Fabric Ducts and traditional metal ductwork represents a pivotal decision with far-reaching implications for efficiency, comfort, and operational costs. Circular Fabric Ducts have emerged as a compelling alternative to their rigid metal counterparts, offering a host of advantages that cater to modern demands in industrial and commercial environments alike.

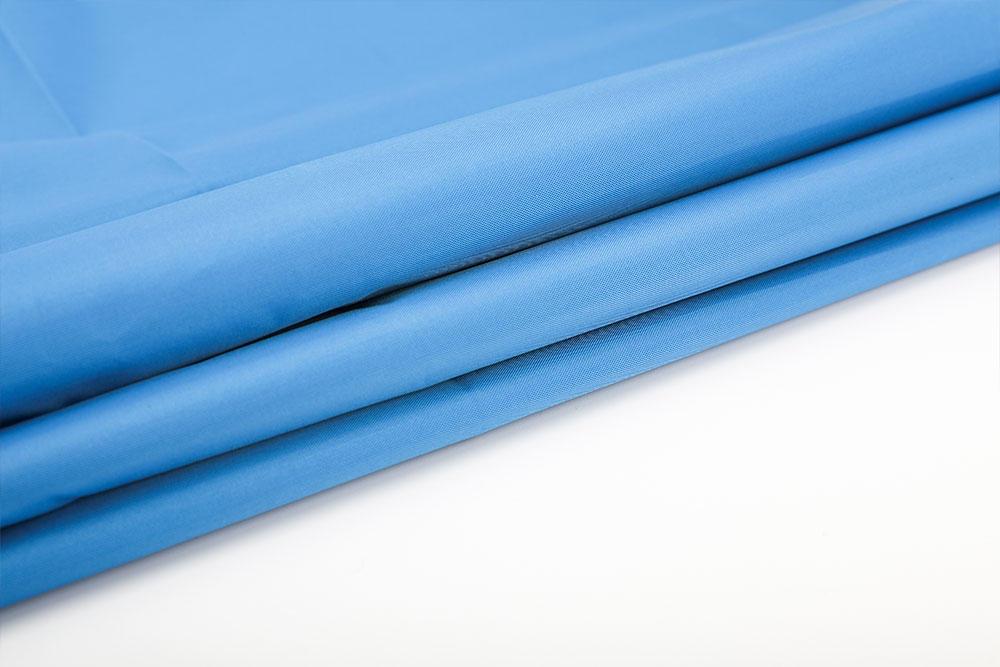

One of the most striking advantages of Circular Fabric Ducts lies in their superior air distribution capabilities. Unlike metal ducts, which often rely on diffusers that can create uneven airflow patterns and drafts, fabric ducts utilize micro seepage or micro porous outlets along their length. This innovative design not only facilitates a large air outlet area but also ensures uniform distribution of conditioned air throughout the space. By minimizing air velocity and eliminating drafts, fabric ducts enhance occupant comfort significantly, creating a more pleasant working environment in industrial settings where maintaining consistent temperatures is crucial.

Energy efficiency is another compelling reason to opt for Circular Fabric Ducts. These ducts operate at lower air speeds compared to metal ducts, which translates to reduced energy consumption and lower operational costs over time. The optimized airflow patterns achieved with fabric ducts ensure that conditioned air reaches its intended destinations efficiently, without unnecessary energy losses often associated with conventional duct systems. This efficiency not only benefits the bottom line but also aligns with sustainability goals, making Circular Fabric Ducts a preferred choice for environmentally conscious industries.

Condensation prevention is yet another advantage offered by Circular Fabric Ducts. Thanks to their ability to maintain nearly uniform temperatures inside and outside the duct, fabric ducts mitigate the risk of condensation forming on the duct surface. This feature eliminates the need for additional insulation, which not only simplifies installation but also reduces material costs and construction timelines. In environments where moisture control is critical, such as food processing facilities or pharmaceutical plants, this anti-condensation property ensures operational continuity and regulatory compliance without compromising on safety or hygiene standards.

The ease of installation and maintenance further distinguishes Circular Fabric Ducts from traditional metal ductwork. Fabric ducts are lightweight and flexible, allowing for straightforward installation using various mounting methods such as cable suspension or track systems. This simplicity accelerates project timelines and minimizes disruption to ongoing operations, offering a significant advantage over the cumbersome installation processes associated with metal ducts. Moreover, fabric ducts are inherently easy to clean and maintain, typically requiring only periodic washing to remove dust and contaminants. This simplicity not only reduces maintenance costs but also prolongs the operational lifespan of the duct system, ensuring reliable performance over the long term.

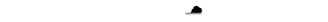

Beyond practical considerations, Circular Fabric Ducts also excel in aesthetic customization and noise reduction. Available in a spectrum of colors and customizable designs, fabric ducts can complement or enhance the architectural aesthetics of any industrial or commercial space. Their ability to blend seamlessly into the environment contributes to a visually pleasing interior while simultaneously reducing noise levels. Operating at lower air velocities, fabric ducts produce minimal noise compared to metal ducts, fostering quieter work environments that promote productivity and concentration among occupants.

The advantages of Circular Fabric Ducts over traditional metal ducts in industrial ventilation systems are compelling and multifaceted. From superior air distribution and energy efficiency to condensation prevention, ease of installation, and aesthetic appeal, fabric ducts represent a modern solution that addresses the diverse needs of today's industrial environments. By embracing these innovative duct systems, businesses can enhance operational efficiency, improve indoor air quality, and achieve significant cost savings over the lifecycle of their ventilation infrastructure. As industries continue to prioritize sustainability and occupant comfort, Circular Fabric Ducts emerge as a cornerstone technology poised to meet and exceed these evolving demands.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español