FR (fire retardant) PU (polyurethane) coated tent fabric stands out in the realm of outdoor textiles for its robust combination of safety, durability, and weather resistance. Tailored for environments where reliability is non-negotiable, such as camping grounds, events, and military operations, these fabrics boast a suite of essential features that make them indispensable.

1. Fire Retardancy

At the core of FR PU coated tent fabric is its ability to resist ignition and inhibit the spread of flames. This critical feature ensures enhanced safety, particularly in settings where open flames, electrical equipment, or cooking activities pose inherent risks. Compliance with stringent fire retardancy standards, such as NFPA 701, underscores its reliability in safeguarding occupants and property.

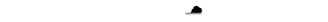

2. Waterproof Performance

The PU coating applied to these fabrics provides exceptional waterproofing capabilities. By forming a protective barrier, FR PU coated fabrics effectively repel water, ensuring that the interior of the tent remains dry and comfortable even during prolonged exposure to rain or moisture. This feature not only enhances user comfort but also protects valuable equipment and gear from water damage.

3. Weather Resistance

Beyond waterproofing, FR PU coated fabrics exhibit resilience against various weather elements. They are engineered to withstand exposure to UV rays, which helps prevent degradation and color fading over time. Additionally, these fabrics offer resistance to wind, maintaining structural integrity and stability during inclement weather conditions.

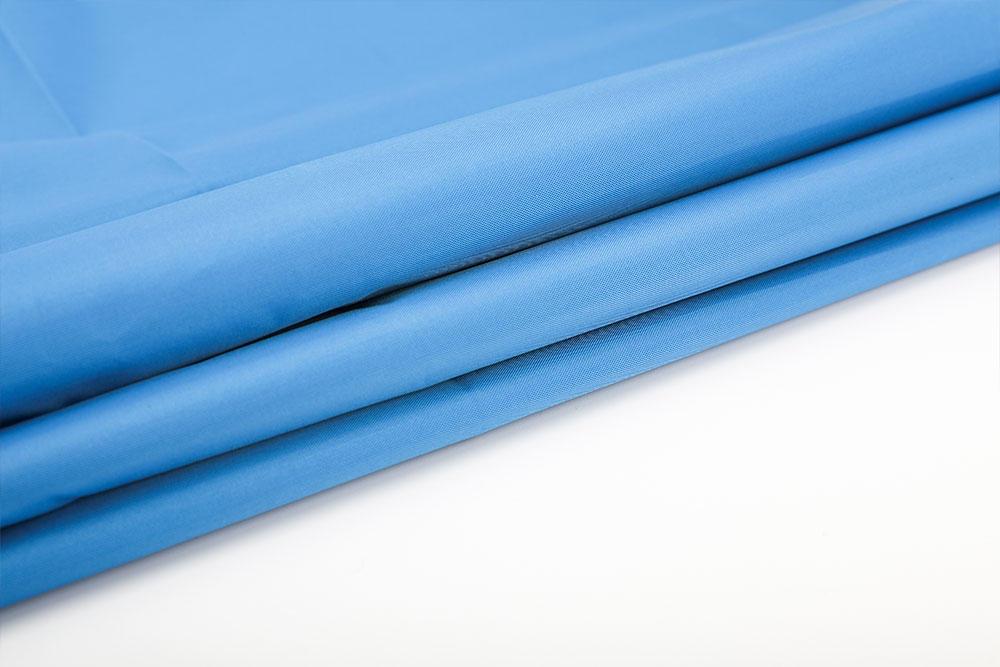

4. Durability and Strength

Designed for rugged outdoor use, FR PU coated tent fabrics are built to be durable and resistant to abrasion, tearing, and punctures. This durability ensures longevity and reliability, allowing the tent to withstand rough handling, frequent setups, and unpredictable outdoor terrain without compromising performance.

5. Lightweight Construction

Despite their durability, FR PU coated fabrics are typically lightweight. This characteristic is advantageous for applications where portability and ease of handling are priorities, such as backpacking tents or emergency shelters. The lightweight nature of these fabrics facilitates easier transportation and setup without sacrificing strength or protection.

6. Breathability

Certain variants of FR PU coated fabrics are engineered to be breathable, allowing moisture vapor to escape from inside the tent. This feature helps mitigate condensation buildup, maintaining a comfortable and dry interior environment. Improved breathability contributes to overall comfort, particularly during humid or warmer weather conditions.

7. UV Resistance

To prolong their lifespan and maintain performance, many FR PU coated fabrics are treated to resist UV degradation. This UV resistance prevents the fabric from weakening or becoming brittle over time due to sun exposure, ensuring sustained reliability and aesthetic appeal in outdoor settings.

8. Anti-Microbial Properties

Some iterations of FR PU coated fabrics incorporate anti-microbial treatments, which inhibit the growth of mold, mildew, and bacteria. This feature is particularly beneficial in humid or damp environments where microbial growth could compromise hygiene and fabric integrity.

9. Ease of Maintenance

FR PU coated tent fabrics are designed for practicality, offering ease of maintenance. They are typically easy to clean and care for, often requiring simple spot-cleaning with mild soap and water or machine-washing as recommended by the manufacturer. This ease of maintenance contributes to prolonged durability and hygiene.

10. Customization Options

Manufacturers may provide customization options for FR PU coated fabrics, including a variety of colors, prints, or textures. This flexibility allows for personalized tent designs that cater to specific aesthetic preferences or branding requirements.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español