When selecting fabric for outdoor tents, especially those intended for camping, events, or military use, the choice of material goes beyond mere aesthetics. Fabric performance, durability, and specific treatments like fire retardancy and waterproofing are crucial considerations. FR (fire retardant) PU (polyurethane) coated fabrics have become popular for their ability to combine flame resistance with weatherproofing, making them ideal for various outdoor applications. However, the pricing of FR PU coated tent fabric can vary significantly based on several key factors:

1. Base Material Quality

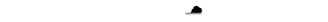

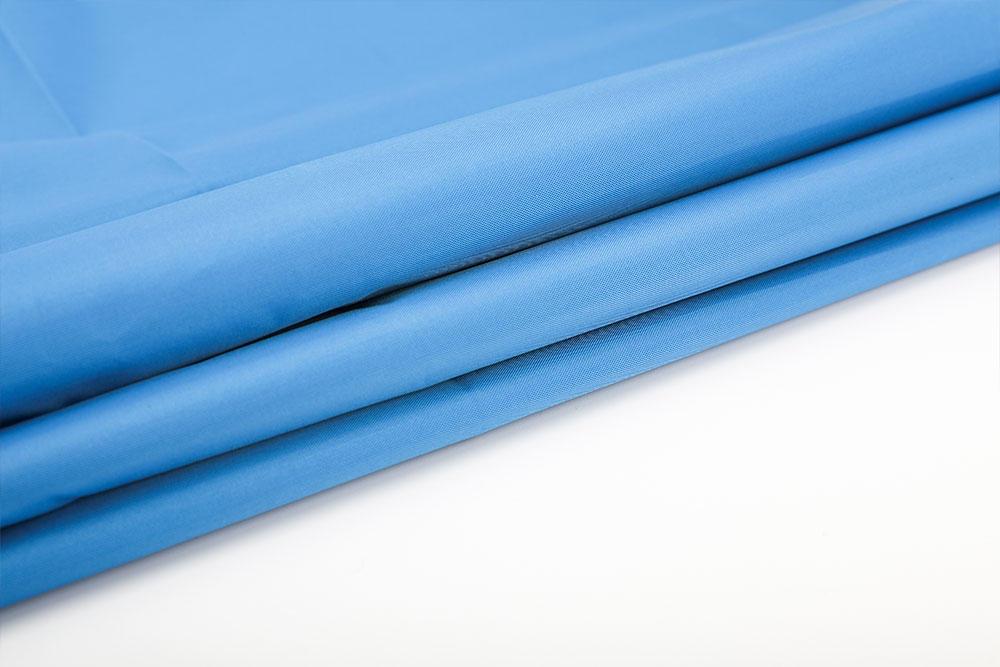

The type and quality of the base fabric used in FR PU coated tent fabric play a significant role in determining its price. Fabrics like polyester taffeta, polyester pongee, and Oxford fabric each offer different levels of durability, strength, and weight. Higher quality materials tend to cost more due to superior performance characteristics and longevity.

2. PU Coating Type and Thickness

Polyurethane (PU) coating is applied to fabrics to enhance their waterproofing capabilities. The type of PU used (standard, silver-coated, pearl paste) and the thickness of the coating affect both the fabric's performance and its price. Thicker coatings generally offer better waterproofing and durability but can increase manufacturing costs.

3. Fire Retardancy Standards

Meeting specific fire retardancy standards, such as NFPA 701 in the United States or similar international standards, requires additional treatments and certifications. Fabrics that comply with these standards undergo rigorous testing processes, which can elevate their production costs and subsequently their selling price.

4. Waterproofing and Additional Treatments

In addition to fire retardancy, FR PU coated fabrics may undergo treatments for enhanced waterproofing, UV resistance, anti-microbial properties, or anti-mosquito capabilities. These additional treatments add complexity to the manufacturing process and may involve specialized chemicals or technologies, contributing to higher costs.

5. Fabric Weight and Density

The weight and density of the fabric impact its durability and performance under various conditions. Heavier fabrics with higher thread count or density typically cost more due to increased material usage and manufacturing complexity. These fabrics often offer better tear resistance and durability over their lighter counterparts.

6. Customization Options

Custom colors, prints, or special textures can personalize tents but often come at an additional cost. Manufacturers may charge higher prices for custom orders due to the need for specialized dyeing processes, printing equipment setup, or meeting minimum order quantities (MOQs).

7. Supplier and Manufacturing Location

The geographic location of the supplier and the manufacturing facilities also influence pricing. Labor costs, overhead expenses, and regulatory compliance vary across regions, affecting the overall cost structure of FR PU coated tent fabrics.

8. Certifications and Compliance

Fabrics that meet specific international standards or certifications, such as ISO standards or REACH compliance in Europe, require additional documentation and testing. Ensuring compliance with these standards adds costs to the production process, which may be reflected in the fabric's pricing.

9. Economic Factors

Market demand, availability of raw materials, and currency exchange rates can all impact the pricing of FR PU coated tent fabric. Fluctuations in these economic factors can lead to price volatility, influencing both manufacturing costs and final retail prices.

10. Order Quantity and Lead Times

The quantity of fabric ordered and the lead times required for production and delivery also affect pricing. Larger orders typically benefit from economies of scale, leading to lower per-unit costs. Conversely, expedited production or shipping options may incur additional charges, impacting overall pricing.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español