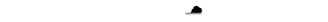

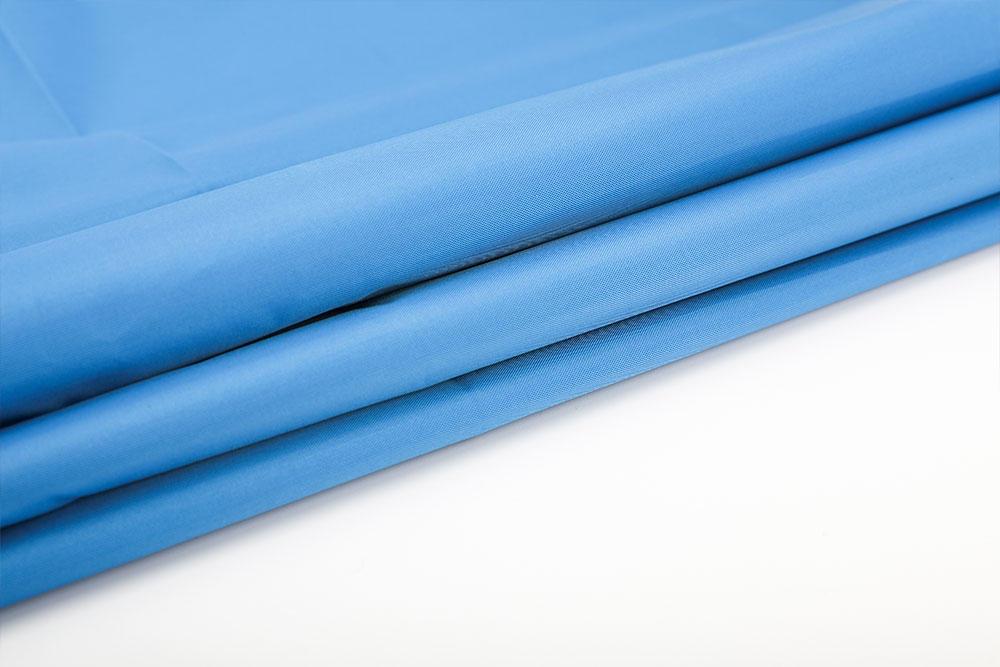

Flame-retardant fabrics and FR Protecting Cover Fabric flame-retardant fabrics are divided into intrinsic fiber flame-retardant fabrics and post-finish flame-retardant fabrics. Post-finish flame-retardant fabrics are divided into two types: disposable flame-retardant, semi-permanent flame-retardant and durable flame-retardant. Intrinsically flame-retardant fabrics are also called permanent flame-retardant fabrics. Intrinsically flame-retardant fabrics use flame-retardant fibers, no matter how many times they are washed with water, the flame retardant performance will never change. In case of fire, it will crimp and carbonize, and it will go out when the fire source leaves. If it does not melt, it will not cause black smoke and will not cause a second fire. Such as aramid flame-retardant fabrics and Molike flame-retardant fabrics are essential flame-retardant fabrics. Usually used for high-end flame-retardant tooling and other flame-retardant work clothes.

The safety is good, the fiber does not melt when exposed to fire, and the low smoke is not poisonous gas. The intrinsically flame-retardant fabric will not affect the flame-retardant performance and environmental protection after washing and friction. With natural fibers as the carrier, the waste can be naturally degraded, which meets the requirements of environmental protection and has excellent intrinsic flame-retardant and fire-resistant performance. It has good heat insulation and anti-static properties in preventing flame spread, smoke release, and anti-melting. With natural fiber characteristics. The fabric has the moisture absorption and release properties of sky fiber, and is soft, comfortable, breathable, and brightly dyed. Aramid essential flame-retardant fabric has permanent flame-retardant, non-melting, non-drip, burning and non-toxic, excellent chemical resistance, and excellent mechanical properties.

The protective clothing made of this fabric will not burn, drip, shrink, or smoke when exposed to fire, especially when it encounters a high temperature of 900-1500 ℃, the fabric surface will quickly carbonize and thicken. The colors of aramid flame-retardant fabrics are orange, dark blue, army green, and brilliant blue. Modacrylic flame-retardant fabrics are made of domestic acrylic or Protex fibers and added a certain proportion of other flame-retardant fibers, conductive fibers and long-staple cotton. . Modacrylic flame-retardant fabrics are usually based on fluorescent yellow colors, followed by navy blue and black. At present, all countries in the world have issued laws and regulations on flame-retardant protective fabrics and flame-retardant protective clothing. China has promulgated the "Regulations for the Implementation of the Work Safety Law of the People's Republic of China" and the "Law of the People's Republic of China on Prevention and Control of Night Shifts" such as GB 8965.1/GB5455.

The European Union has issued the "Directive on Equipping Workers with Personal Protective Equipment in the Workplace to Meet Minimum Health and Safety Requirements" such as EN ISO 11612. The United States has introduced the "Occupational Safety and Health Act" and "Employers' Expenditure on Personal Protective Equipment" and "Occupational Safety and Health Administration" (OSHA) such as NFPA 2112/ASTM6413. Various functional fabrics such as flame-retardant fabrics, anti-arc fabrics, fluorescent fabrics, anti-static fabrics, etc., all adopt advanced production technology, soft to the touch, full color, and the number of wash-resistances can exceed European and American standards. After BTTG, SGS, ARCWEAR, KINECTRICS, BV, ITS and other authoritative organizations, the product can pass EN11611, EN11612, EN61482, EN20471, EN1149 and many other EU testing standards as well as GOST, DIN, NFPA2112, NFPA70E, ASTM D 1506, ANSI107 and other national testing standards.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español