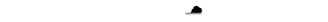

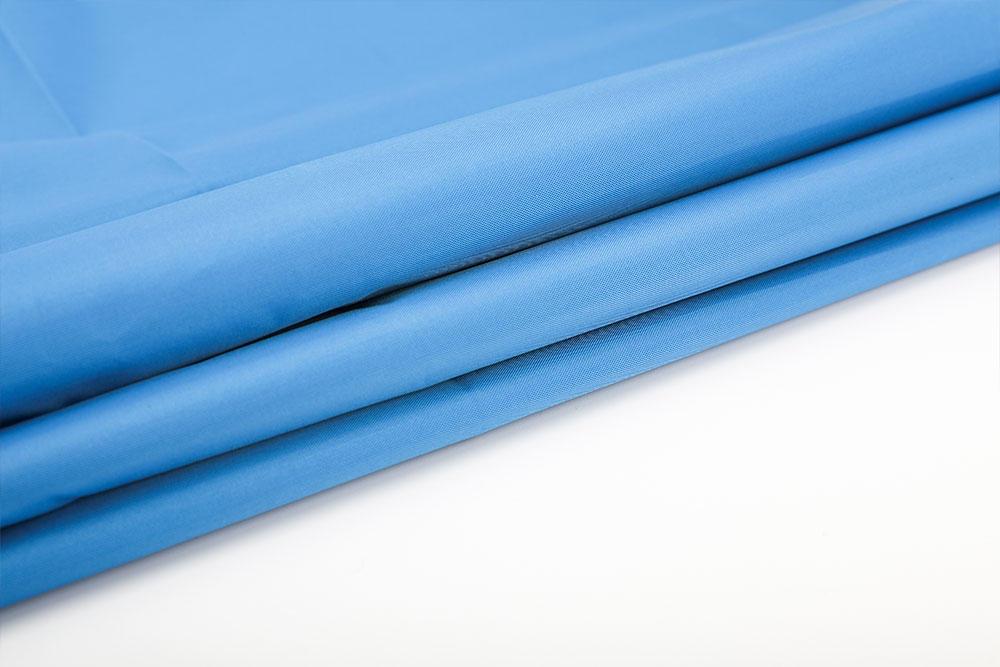

When flames, sparks or intense FR Protecting Cover Fabric heat reach flammable substances, chemical reactions occur, producing heat and light. This reaction is called "combustion" and is the basis of fire. Have you ever wondered how protective flame-retardant fabrics can prevent fire? Arc flash, flash fire, and combustible dust hazards are common in many industrial environments, including oil, gas, and power industries. Wearing FR personal protective equipment daily can provide ultimate protection for people who may suffer from these short-term thermal hazards. However, to provide this critical protection, PPE must utilize the scientific knowledge behind fire and flame retardant fabrics.

To develop effective flame-retardant fabrics, textile manufacturers must first have a deep understanding of fire protection science. Manufacturers have developed different technologies to manufacture FR textiles, each with its own advantages. To help you understand how these methods extinguish flames, we explained the various techniques, discussed their advantages and disadvantages, and provided some insights into how they can be used as flame retardants. With a deep scientific understanding of fires, fabric manufacturers have developed flame retardancy strategies that focus on removing one of the components needed to maintain the fire.

All of these technologies are designed to extinguish flames and reduce the risk of injury to the wearer, but each has its own advantages. Since each technology can be used permanently during the life of the protective clothing and will not be washed away due to washing, the choice of technology will depend on the specific hazards and preferences for other attributes. There is no one technique that is best for all dangerous situations. For example, electrical workers who may be at risk of arc flashover, petrochemical workers who may be at risk of flashover, and firefighters who are exposed to longer fuel fires may all need different techniques. Flame retardant protective clothing.

In consideration of industry requirements, working environment, comfort and employee preferences, the FR fiber manufactured by the manufacturer is not only tailored to the possible thermal hazards at the work site, but also provides continuous protection day after day. Coke formers are phosphorus-based flame retardants that can be incorporated into fibers or fabrics. They are mainly used for cellulosic fibers, such as cotton, rayon or lyocell fibers. When these fabrics are exposed to fire and the fibers begin to decompose into gaseous fuel, the phosphorus reagent reacts with fuel molecules to form stable solid carbon. The charcoal not only consumes gaseous molecules, otherwise it will become a burning fuel, but also forms a barrier between the flame and the fabric and prevents the fabric from further decomposition and release more fuel.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español