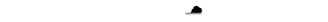

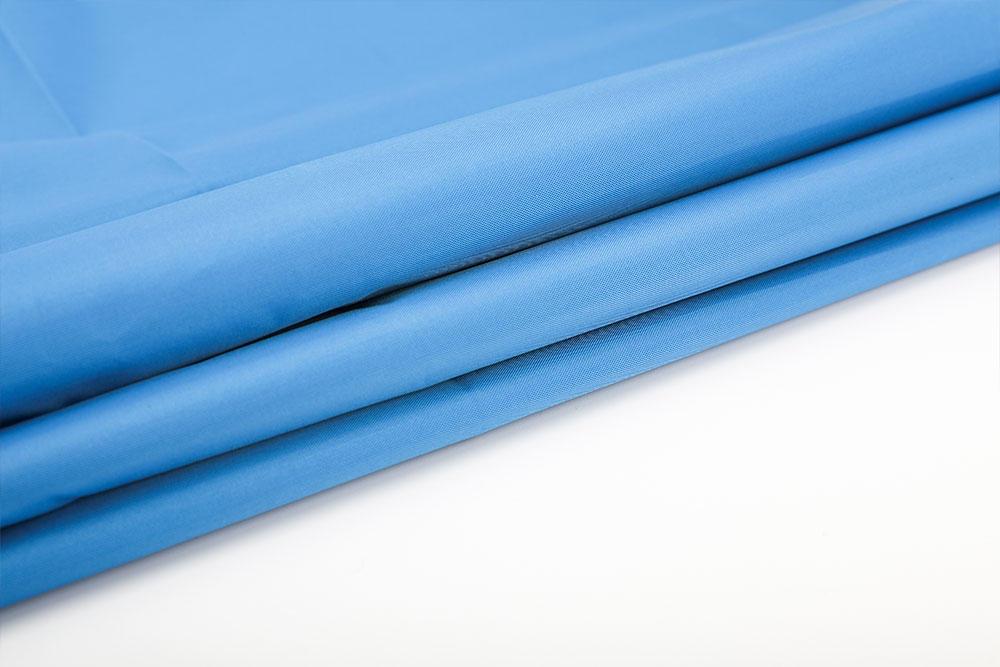

This standard FR Protecting Cover Fabric applies to industrial furnaces, metal thermal processing, welding, chemical, petroleum and other places engaged in open flames or sparks or operations near molten metal, and when working in places with combustible substances and fire hazards. Flame-retardant protective clothing hereinafter referred to as flame-retardant clothing to reduce the human body from fire damage due to the burning of clothing. Flame-retardant protective clothing: refers to protective clothing that can slow down the spread of flames and carbonize clothing to form an isolation layer after directly receiving flames and hot objects to protect the safety and health of the human body. Flame-retardant clothing must have ventilation holes in suitable places to facilitate perspiration and regulate body temperature. However, the ventilation pores must not affect the structural strength of the clothing, and the pore structure must not allow foreign objects to enter the clothing.

Use fabrics that have been fire-retardant and can withstand multiple washings synthetic washing powder is built into the washing machine, according to the general washing concentration, temperature 60℃, washing time 15min, washing more than 50 times. Do not use hot-melt fabrics that can accumulate static electricity and discharge. The hook should be easy to connect and release. The material of the buckle and hook shall not be made of fusible and flammable materials if the buckle or hook is sewn into the garment, it is not subject to this restriction. Cut a test piece with a center width of 50mm and a length of 200mm at the suture point from the four parts of the finished clothes and trousers, and install it on a tensile testing machine. A tensile test was performed at the tensile speed, the breaking load of each test piece was obtained, and the lowest value was taken as the tensile strength of the joint.

The fabric after flame retardant finishing is qualified if it reaches the second level. The first class is an excellent product. After 50 times of washing, the test cloth shall not be lower than Grade 3. In the test, the textile product is found to be unqualified when it is found to have melting and shrinkage. The production of flame-retardant fabrics and the production of flame-retardant clothing products need to be supervised by the quality supervision and inspection department designated by the state. The products of the production plant or garment factory and the user department shall be checked regularly. When the product is found to be unqualified, it shall be re-inspected in the same batch of products.

If the re-inspection is still unqualified, the batch of products shall be immediately stopped for sale and pending treatment. During the three-year storage period, the flame retardant performance of the product should be basically stable, and the connecting parts should be firm and reliable. Products that have been stored for an extended period of time shall be submitted for inspection in accordance with regulations and re-qualified. The quality performance test of the textile fabric used in the product is undertaken by the corresponding unit of the textile department. The manufacturer is responsible for product self-inspection and is responsible for its product quality. During transportation and storage, avoid exposure to the sun, rain and moisture, and not put it together with acids, alkalis, oils and corrosive materials. The storage warehouse should be kept ventilated and dry.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español