The FR Coated Fabric retardancy of the fabric is often realized through the principles of gas phase flame retardant, condensed phase flame retardant and interrupted heat exchange flame retardant. It is gas phase flame retardant that inhibits the growth of the combustion reaction chain and freely exerts the function of flame retardant fabric; it retards or prevents the thermal decomposition of polymer in the solid phase and acts as a condensed phase flame retardant; part of the heat generated by the combustion of the polymer The flame retardant caused by taking away belongs to the flame retardant of interrupting the heat exchanger. However, both combustion and flame retardancy are very complicated processes, involving many influences and factors. It is difficult to strictly divide the flame retardant mechanism of a flame retardant system into a certain type.

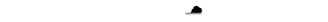

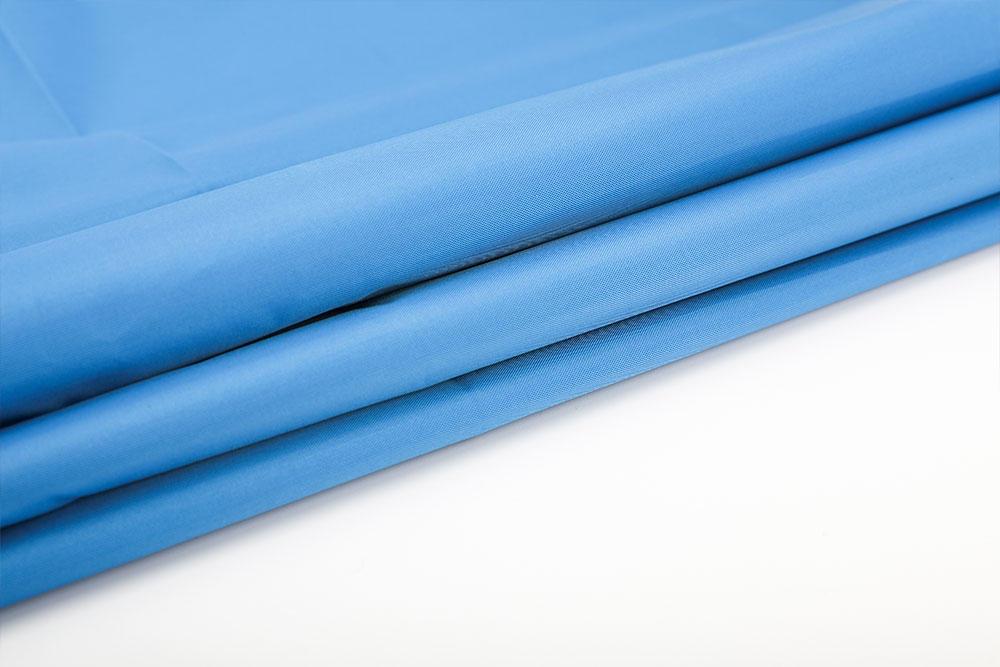

In fact, many flame retardant systems use several types of flame retardants at the same time. The combustion principle works.It can also protect the original performance of the fabric, meet the requirements of the international flame retardant protective clothing", and at the same time can meet the European Union and other standards. Requirements for first-class flame retardant fabrics. The fabric has good washing resistance, non-toxic and odorless, safe and reliable to the human body, breathable and moisture-permeable, soft to the touch, and comfortable to wear. It is suitable for metallurgy, machinery, material industry, fire protection and other industries. It can also be used as a washable flame-retardant finishing fabric for decorative fabric polyester products. This product does not contain halogen, meets ecological and environmental protection requirements, is convenient to use, and can be applied to conventional equipment.

Its main technical indicators are at the international leading level. The flame retardant ATP can achieve excellent flame retardant effect with low dosage. The flame retardant finishing does not affect the feel and appearance of the fabric. The flame retardant ATP has a colorless to light yellow transparent viscous, specific gravity phosphorus content greater than 19, PH: 4-6, soluble in water.Flame-retardant fabrics refer to fabrics that can be automatically extinguished even after leaving the open fire city. It will burn when exposed to fire. Flame-retardant fabrics can be divided into post-finish flame-retardant fabrics and intrinsic flame-retardant fabrics permanent flame-retardant fabrics.

Post-finished flame-retardant fabrics are post-processed flame-retardant fabrics, which are produced by coating and auxiliary treatment during dyeing and finishing. After washing, the flame-retardant effect will gradually weaken, and it is generally used to produce things that are not often washed. Essentially flame-retardant fabrics are permanent flame-retardant fabrics, which are formed by weaving flame-retardant fibers and then dyeing and finishing. Flame-retardant fibers are added to the flame-retardant fiber during the drawing process and fused with the fiber. No matter how many times it is washed, its resistance The burning effect is undiminished. The post-treatment flame retardant cost is lower, the flame retardant fiber cost is higher, and the permanent flame retardant fabric should be woven with 99.99% flame retardant fiber and cannot be interwoven with other fibers.

Email: [email protected]

Email: [email protected] Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español