Details:

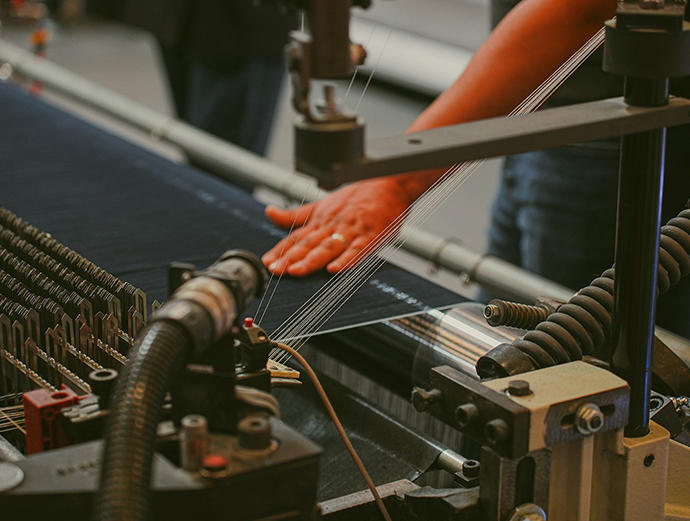

Name:Inherently fire retardant blackout curtain fabric for hotel

Code: KLB-FR-004

Note:Made by 99.99% IFR polyester yarn, comfortable hand feeling, black yarn in the middle, blackout percentage can reach more than 85%, high level quality, keep flame retardant after 50 times washing.

Application: Curtain

Material: 99.99% FR Polyester

Function: Fire retardant, Blackout

Treatment: Piece dye

Width: 280cm

Weight: 250gsm

|

PROPERTY |

Items |

Index |

Results |

Standard |

Lab |

Note |

|

|

Flame retardancy |

B |

Fire growth rate index used for classification purposes, W/S≤120 |

0 |

GB8624-2012; |

NFTC, SGS |

Tested after 50 times washing |

|

|

Total heat release within 600s, MJ≤7.5 |

1.4 |

||||||

|

No lateral flame spread to the edge of the specimen (LFS), m |

Pass |

||||||

|

Flame spread (Fs), mm≤150 within 60s |

33 |

||||||

|

No ignite the paper |

Pass |

||||||

|

S1 |

Smoke growth rate (SMOGRA),m2/s2≤30 |

0 |

|||||

|

Total smoke production within 600s (TSP600S),m2 |

40 |

||||||

|

d0 |

No flaming droplets/particles within 600s |

Pass |

|||||

|

t0 |

Smoke Toxity (For GB8624 only) |

ZA1 |

|||||

|

Oxygen Index≥32 |

35 |

||||||

|

Burning length≤150mm |

65 |

||||||

|

After flame times≤5s |

0 |

||||||

|

B1 |

Afterglow times≤5s |

0 |

GB8624-1997; |

NFTC, SGS |

Tested after 50 times washing |

||

|

No ignite the absorbent cotton |

Pass |

||||||

|

Smoke density rate (SDR)≤15 |

3 |

||||||

|

Smoke Toxity rate less than ZA2 |

ZA1 |

||||||

|

B1 |

Reaching the measuring mark within 20s |

No |

DIN 4102-1( May 1998) |

SGS |

|

||

|

Self extinguish of the flame(s) |

13 |

||||||

|

End of after flaming(s) |

13 |

||||||

|

End of after glowing(s) |

13 |

||||||

|

Molten dripping |

No |

||||||

|

M1 |

NF P92 503:1995 |

Hole |

|

NF P92-507:2004 |

SGS |

|

|

|

Max after flame time withdrawal the pilot flame(s) |

0 |

||||||

|

After grow time(s) |

0 |

||||||

|

Flaming debris |

No |

||||||

|

Non-flaming debris |

Yes |

||||||

|

White-hot spots with propagation effects |

No |

||||||

|

Max destruction length from the lower edge |

15 |

||||||

|

Max width of the destroyed zones between 250mm and 600mm |

Non-detected |

||||||

|

Flaming molten droplets |

No |

||||||

|

M1 |

NF P92 505:1995 |

Non-flaming molten droplets |

Yes |

||||

|

Ignite the wadding |

No |

||||||

|

NFPA 701:2010 Method 1 |

Mass loss≤40% |

22.7% |

NFPA 701:2010 |

SGS |

Tested after 5 times washing |

||

|

After flame time(s) |

0 |

||||||

|

Burning time on floor(s) |

0 |

||||||

|

Physics property |

Shrinkage rate |

Warp≤±2% |

-1.3% |

FZ/T72001-2009 |

Local Lab |

|

|

|

Weft≤±2% |

-1.1% |

||||||

|

Color fastness |

Changing in shade≥3-4 |

4 |

|||||

|

Staining on cotton≥3-4 |

4 |

||||||

|

Staining on polyester≥3-4 |

4-5 |

||||||

|

Formaldehyde |

≤300mg/KG |

0 |

|||||

|

PH value |

4.0-9.0 |

6.3 |

|||||

Email:

Email:  Tel: +86-512-63221899

Tel: +86-512-63221899

English

English Español

Español

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)